86-0533-7323899

Our plate-type heat exchangers, which are typical of their high exchanging efficiency, less loss in material flow resistance, compact structure, delicate temperature control, elastic operation, easy installment and long time use, are by far the most advanced high-efficiency energy-saving heat exchanging equipment in the country.

1.Technical Data

Heat exchanging area of one plate: 1.80 m2

Space between plates: 4.3 mm

Crosssectional area of one flow passage: 0.00321 m2

Maximum disposal volume: 1038 m³/h

Whole length of flange: 350 DN mm

Working temperature: ≤150℃

Working pressure: 1.0 Mpa

Diameter of angle holes: 350 mm

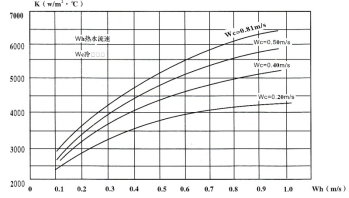

Line graph of heat coefficient-speed(water-water)

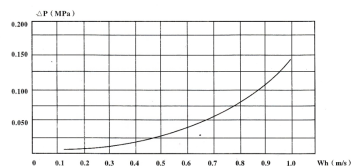

Graph of pressure decrease -speed

2.MBR1.8Parameter

outside size of plate*( mm) | 2245×995×0.6 | normal ripple pitch( mm) | 13 |

effective heat exchanging area (m2) | 1.8 | width of flow passage (mm) | 942 |

weight of one plate (kg) | 9.5 | average space between plates (mm) | 4.3 |

diameter of angle hole (mm) | Ф350 | average crossed sectional area (m2) | 0.00321 |

height of ripple (mm) | 3.7 | average equivalent diameter(mm) | 7.4 |

form of ripple | isosceles triangle | material of plate | 304 316 316L Ti |

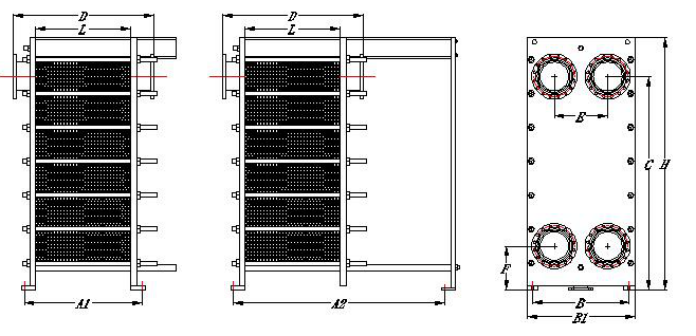

3.Installing Size of MBR1.8

Floor-type Hanging type

B=1030 C=2273 F=463 E=568 H=2691 B1=1150 DN≤350 PN1.0

Heat exchanging area(m2) | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

Plate number (sheet) | 84 | 112 | 139 | 167 | 195 | 223 | 250 | 278 | 306 | 334 |

L (mm) | 361 | 482 | 598 | 718 | 839 | 959 | 1075 | 1195 | 1316 | 1436 |

D(mm) | 841 | 962 | 1078 | 1198 | 1319 | 1439 | 1555 | 1675 | 1796 | 1916 |

A1 (mm) | 601 | 722 | 838 | 958 | 1079 | 1199 | 1315 | 1435 | 1556 | 1676 |

A2 (mm) | 1500 | 1700 | 1900 | 2050 | 2250 | 2400 | 2600 | 2800 | 2950 | |

Weigh(mm) | 3833 | 4128 | 4423 | 4728 | 5032 | 5340 | 5632 | 5938 | 6245 | 6549 |