86-0533-7323899

Our plate-type heat exchangers can deal with different kinds of material ranging from common industrial water to high-viscosity liquid, from food liquid and medical material which need high requirements for sanitation to acid-based solution, from liquid containing granules to suspending liquid with a little fiber.

1.Technical Data

Heat exchanging area of one plate : 0.4095 m2

Space between plates: 4.0 mm

Crosssectional area of one flow passage: 0.001353 m2

Maximum disposal volume: 200 m³/h

Whole length of flange: 125 DN mm

Working temperature: ≤150 ℃

Working pressure : 0.6,1.0,1.25 Mpa

Diameter of angle holes: 125 mm

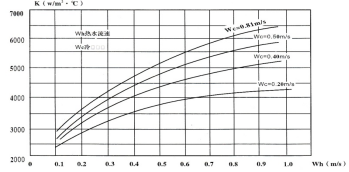

Line graph of heat coefficient-speed(water-water)

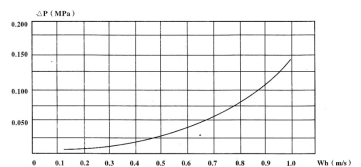

Graph of pressure decrease -speed

2. MBR0.4Parameter | |||

Outside size of plate(mm) | 1220×460×0.6 | Normal ripple pitch(mm) | 13 |

Effective heat exchanging area(m2) | 0.4095 | Width of flow passage(mm) | 410 |

Weight of one plate(kg) | 2.5 | Average space between plates(mm) | 4 |

Diameter of angle hole(mm) | Ф125 | Average crossed sectional area(m2) | 0.001353 |

Height of ripple(mm) | 3.3 | Average equivalent diameter(mm) | 6.6 |

Form of ripple | Isosceles triangle | Material of plate | 304 316 316L Ti |

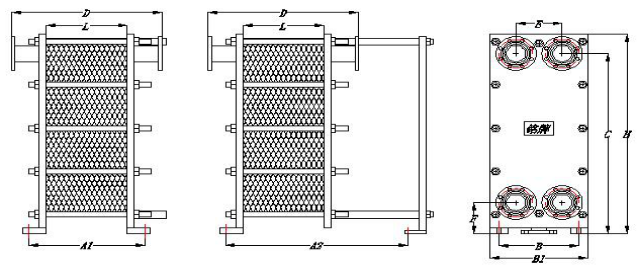

3. Installing Size of MBR0.4

Floor-type Hanging type

B=460 C=1203 F=176 E=270 H=1340 B1=550 DN≤125 PN1.0

Heat exchanging area(m2) | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 |

Plate number(sheet) | 76 | 88 | 101 | 113 | 126 | 138 | 151 | 163 | 176 |

L (mm) | 304 | 352 | 404 | 452 | 504 | 552 | 604 | 652 | 704 |

D (mm) | 712 | 760 | 812 | 860 | 912 | 960 | 1012 | 1060 | 1112 |

A1(mm) | 484 | 532 | 584 | 632 | 684 | 732 | 784 | 832 | 884 |

Weight (kg) | 676 | 714 | 755 | 792 | 833 | 870 | 910 | 948 | 989 |

A2 (mm) | 1200 | 1400 | 1670 | ||||||

4.Plate material:

1.SUS304 SUS316L

2.Titanium and Palladium

3.Hadtelloy Alloy

4.Nickel

5.Design features

1.High efficiency and low Consumption: Its heat exchanging parameter is 2000-4500kcal/m2.℃.h, which is several times higher than of cellpacking heat exchanger.

2.Compact structure: Plate-type heat exchanger is arranged compactly. Compared with other types of heat exchanger, it takes up less area and space. It is only 1/5 the size of line-type heat exchanger, considering the same area.

3.Easy cleaning convenient dismantlement: Set flat and plate are held together by twisting bolts. Therefore it is convenient to dismantle. You can clean it whenever you like.what’s more, it’s not easy to get scale because of its smooth flat surface and high frequent flowing.

4.Long using time: plate-type heat exchanger is made of rustless steel or titanium alloy. It can endure corrosion of different kinds of medium. The rubber pad can be changed freely. It is convenient to dismantle or test.

5.Strong adaptability: The plates are separate units. It can increase or decrease flowing according to requirement. From is varied. It can be used for different technological requirements.

6.No mixed liquid: There is a liquid passage in the sealed groove. Every medium cannot be mixed together. Medium runs out even when there appears leakage.