86-0533-7323899

Our plate-type heat exchangers can deal with different kinds of material ranging from common industrial water to high-viscosity liquid, from food liquid and medical material which need high requirements for sanitation to acid-based solution, from liquid containing granules to suspending liquid with a little fiber.

1.Technical Data

Heat exchanging area of one plate: 0.308 m2

Space between plates: 4.3 mm

Crosssectional area of one flow passage: 0.00118 m2

Maximum disposal volume: 120 m³/h

Whole length of flange:: 80 DN mm

Working temperature: ≤150 ℃

Working pressure: 0.6, 1.0, 1.25 Mpa

Diameter of angle holes:: 80 mm

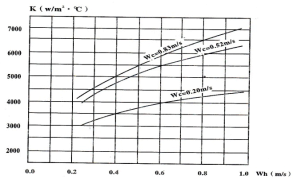

Line graph of heat coefficient-speed(water-water)

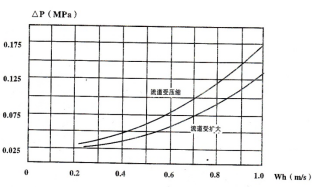

Graph of pressure decrease -speed

2.BR0.3Parameter

outside size of plate(mm) | 1135×370×0.6 | normal ripple pitch(mm) | 15 |

effective heat exchanging area(m2) | 0.308 | width of flow passage(mm) | 320 |

weight of one plate(kg) | 1.95 | average space between plates(mm) | 4.3 |

diameter of angle hole(mm) | Ф80 | average crossed sectional area(m2) | 0.00118 |

height of ripple(mm) | 3.7 | average equivalent diameter(mm) | 7.0 |

form of ripple | isosceles triangle | material of plate | 304 316 316L Ti |

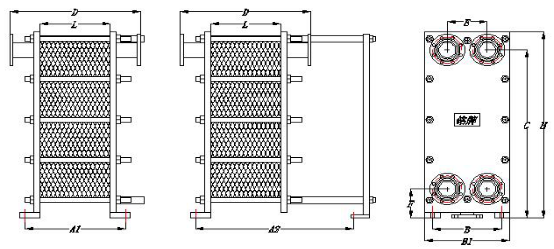

3.Installing Size of BR0.3

Floor-typ Hanging type

B=370 C=1135 F=145 E=224 H=1245 B1=460 DN≤80 PN1.0

Heat exchanging area (m2) | 12 | 15 | 18 | 20 | 22 | 25 | 28 | 30 | 35 | 40 | 45 | 50 |

Plate number (sheet) | 40 | 50 | 60 | 67 | 74 | 84 | 94 | 100 | 117 | 134 | 150 | 167 |

L (mm) | 172 | 215 | 258 | 288 | 318 | 361 | 404 | 430 | 503 | 576 | 645 | 718 |

D (mm) | 532 | 575 | 618 | 648 | 678 | 721 | 764 | 790 | 863 | 936 | 1005 | 1078 |

A1(mm) | 352 | 395 | 438 | 468 | 498 | 541 | 584 | 610 | 683 | 756 | 825 | 898 |

Weight (kg) | 435 | 458 | 483 | 499 | 515 | 540 | 564 | 578 | 619 | 659 | 696 | 736 |

A2 (mm) | 835 | 890 | 950 | 990 | 1025 | 1080 | 1140 | 1180 | 1280 | 1370 | 1470 | 1570 |

4. Notice for Order

a. According to the different requirements of customers, our joint pipe flange isdivided into carbon steel and rustless steel. So be sure to write the specification models of heat exchanger and the material of joint pipe and flange clearly.

b.Sealed pads we provide are usually oil-proofed rubber pad. We can provide pads with special material according to special requirements. Now we mainly produce nitrile rubber pad, triple ethylene propylene rubber pad, chloroprene rubber pad and sanitation pad in four colors: black, white, orange and green.

c.The flow of the equipment can be arranged according to customers’s requirements. If the customers cannot choose type and calculate, we can provide the service of calculating and arranging flow and heat exchanger area.